PROCESS CONTROL SYSTEM – TYPES OF PROCESS

Type of

processes carried out in modern manufacturing industries can be grouped into 3

general areas in term of the kind of operation that takes place:

a.

Continuous process

Is one in which raw materials enter one end

of the system and the finished product comes out the other end of the system.

The picture shows a continuous process

engine assembly line. Engine blocks are fed into one end of the system and

completed engines exit at the other hand. In the continuous processes, the

product material is subjected to different treatment as it flows through the

process (in this case, assembly, adjustment, and inspection). Auto assembly

involves the use of automated machines or robots. At each station, parts are

supplied as needed.

b.

Batch production

In batch processing these is no flow of

product material from one section of the process to another. Instead, asset

amount of each of the input to the processes is received in a batch and then

some operation performed on the batch to produce a finished product or an

intermediate product that need further processing. Each batch of the product

may different.

c.

Individual products production

The individual product production process

is the most common of all processing system. A series of operation produces a

useful output product. The item that produced maybe required to be bent,

drilled, welded, and so on at different step in the process. The workpiece is

normally a discrete part that must be handled on an individual basis.

The control of machines or processes can be

divided into the following categories:

·

Electromechanical control

·

Hardwired electronic control

·

Programmable Hardwired electronic control

·

Programmable logic control (PLC)

·

Computer control

Possible control configuration include:

a.

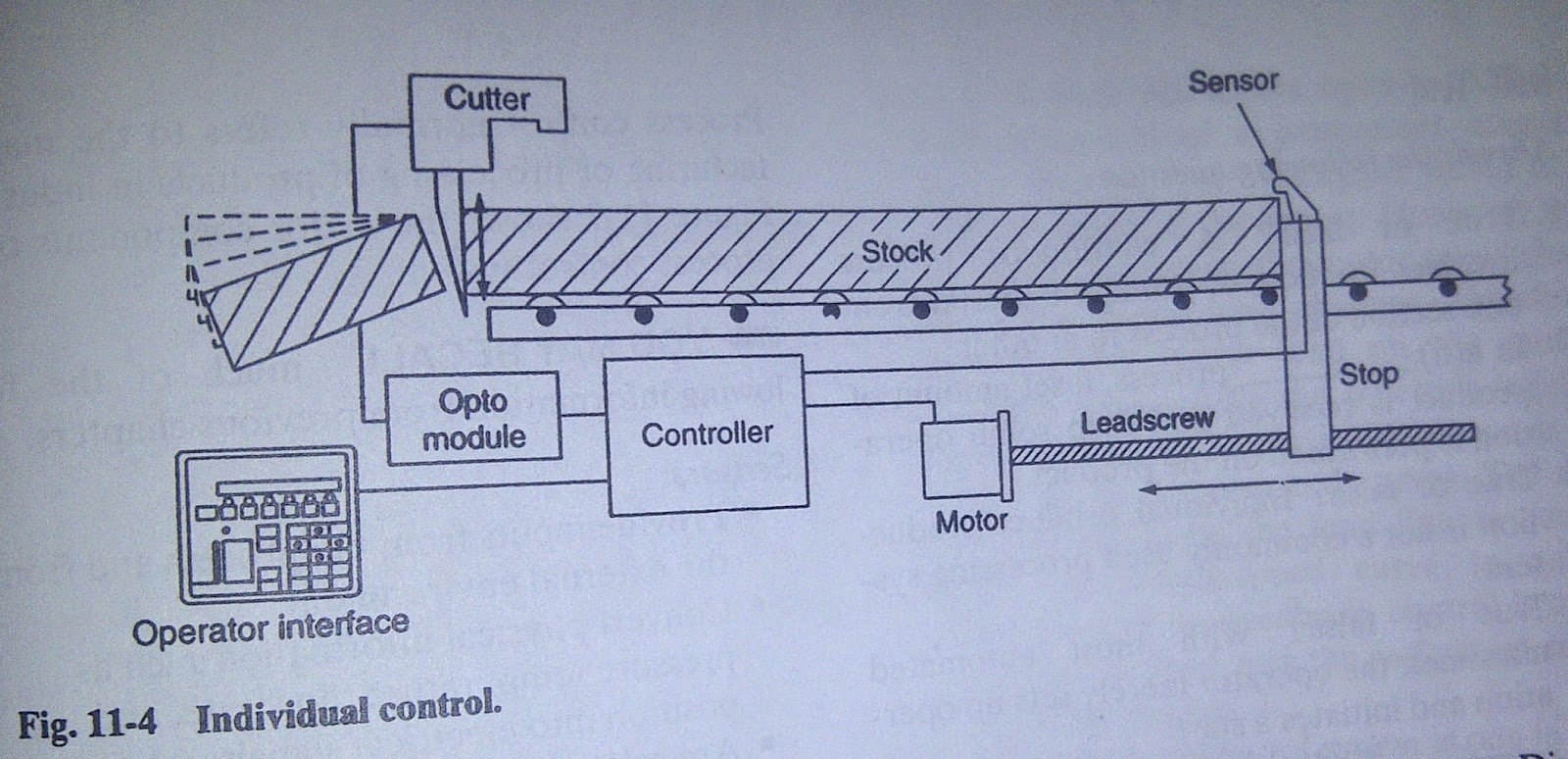

Individual control (is used to control single

machine, doesn’t normally required communication with other controller)

b.

Centralized control (is used when several

machines or processes are controlled by one central controller. This control

layout utilizes a single large control system to control many diverse

manufacturing processes and operation. Each individual step in the

manufacturing process is handled by a central control system controller. No

exchange of controller status or data is sent to other controller)

c.

Distributed control (differs from centralized

system in that each machine is handled by a dedicated control system. Each

dedicated control is totally independent and could be removed from the overall

control scheme if it were not for the manufacturing function perform.

Distributive control involved two or more computer communicating with each

other to accomplish the complete control task)

Petruzella, Frank. 1996. Industrial Electronics. Mc-Graw Hill. Singapore

Tidak ada komentar:

Posting Komentar